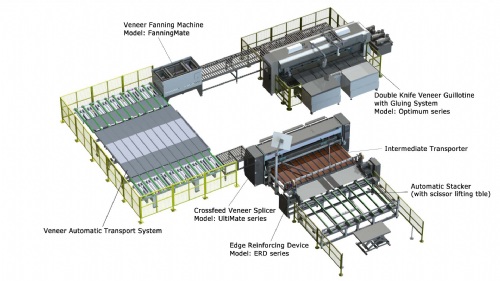

Smart Veneer Faces Production Line (Double Knife Veneer Guillotine with Gluing System + Crossfeed Veneer Splicer)

Model: Optimum series + UltiMate series

Category: Veneer Splicer

Exhibitor: INNOVATOR MACHINERY CO., LTD.

Booth No: A112

Characteristic

Smart Veneer Faces Production Line particularly designed for automated production of our customer not only reduces labor costs but minimizes the breakage of veneer faces by manual carrying. This line brings a typical eight to ten person process down to just two to three people. In order to enhance the overall function of the production line, the double knife veneer guillotine and crossfeed veneer splicer were optimized. The improved equipment significantly increases efficiency and accuracy. FIFO (First In First Out) system can even control the waiting time for glued veneer strips to improve splicing effects. Capacity: 1000 pieces of 4’ x 8’ veneer faces can be produced during 8 hours a day on average.

Related Products

-

Longitudinal Veneer Splicer (integrated gluing system)

-

Single Knife Veneer Guillotine

-

Crossfeed Veneer Splicer

-

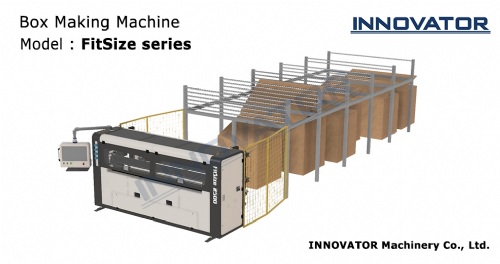

Box Making Machine

-

Longitudinal Veneer Splicer (integrated gluing system)

-

Double Knife Veneer Guillotine

-

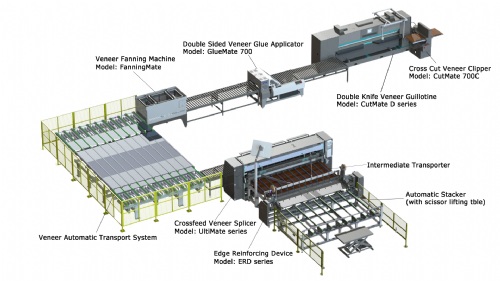

Smart Veneer Faces Production Line (Double Knife Veneer Guillotine + Crossfeed Veneer Splicer)

-

Longitudinal Veneer Splicer

Highest Rated Products