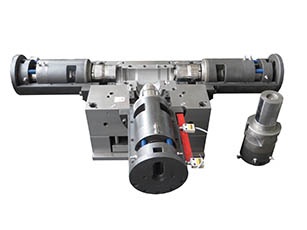

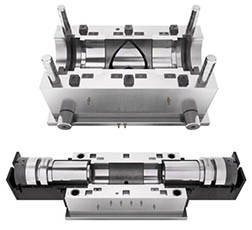

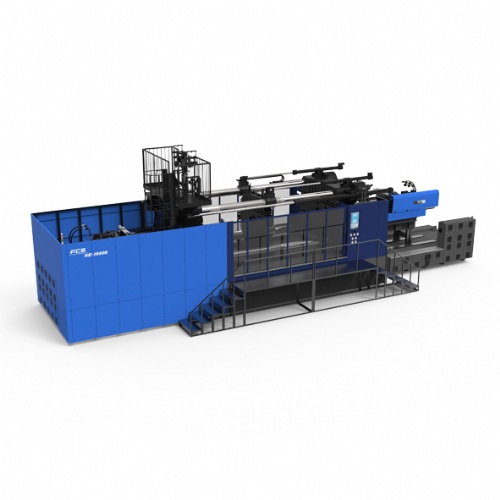

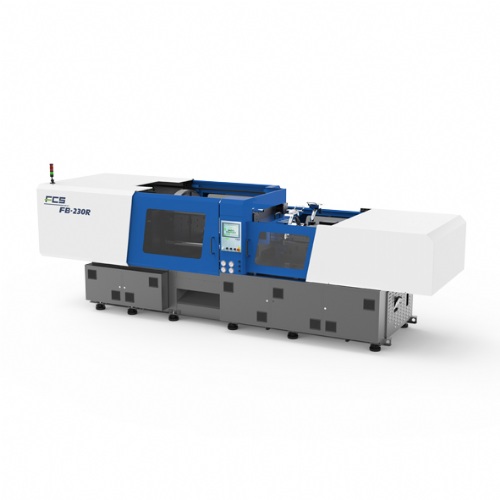

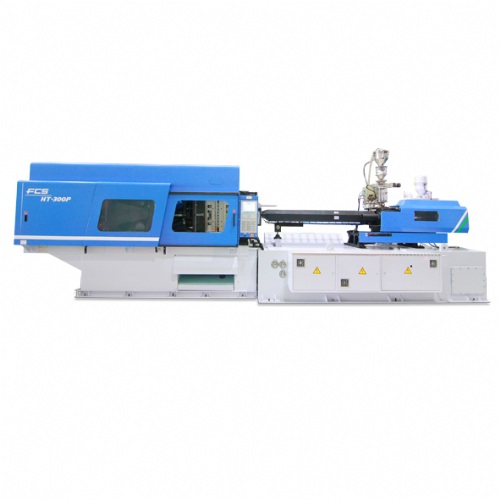

All-Electric Two-Component Injection Molding Machine

Model: CT-R series

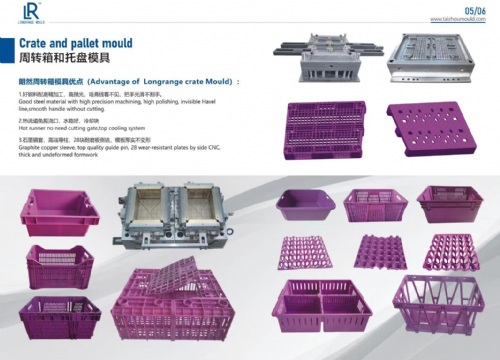

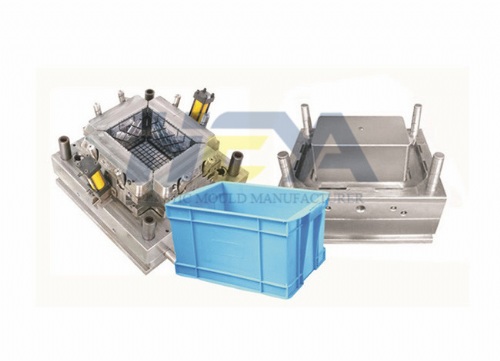

Category: Injection Mould

Exhibitor: FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD.

Booth No: 129

Characteristic

‧ The rate of servo rotary table improved by 30%-50%, which could shorten the cycle time, make switch speed more stable and positioning precision up to 0.005°, and let injection molding products

more precise and stable.

‧ The tie bars are not held by the platens to reduce pollution, abrasion and power consumption, which is suitable for medical products.

‧ Intelligent mold clamp low-pressure protection, reduces the risk of mold crush.

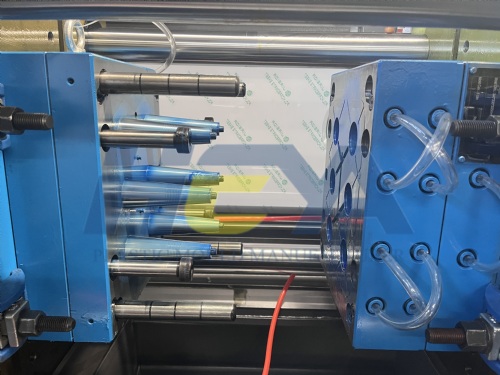

‧ Adopting servo motor and multiple independent barrels for injection, greatly shortens the cycle time.

‧ Linear guide at injection unit makes back pressure approach 0 when charging, reduces the melt overflow.

‧ Barrel heating zones are accurate to 0.1℃ to ensure stable material plasticizing. Screw position is controlled within 0.01 mm to precisely control the shot size and cushion position.

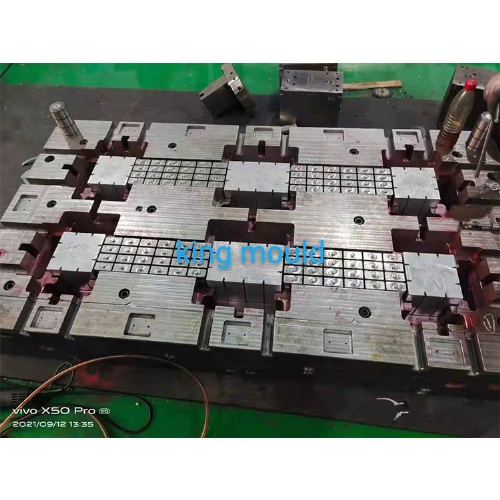

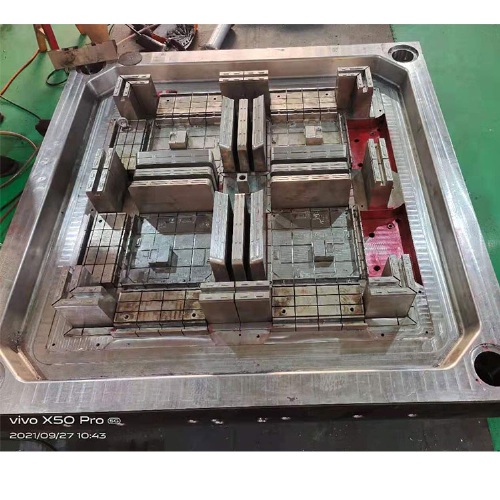

Related Products

-

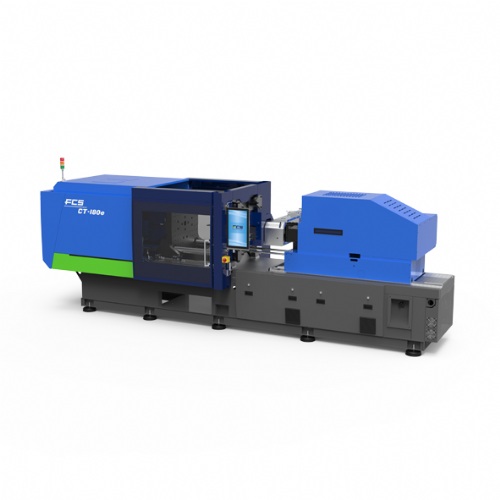

Large Horizontal Rotary Table Two-Component Injection Molding Machine

-

Rotary Table Two-Component Injection Molding Machine

-

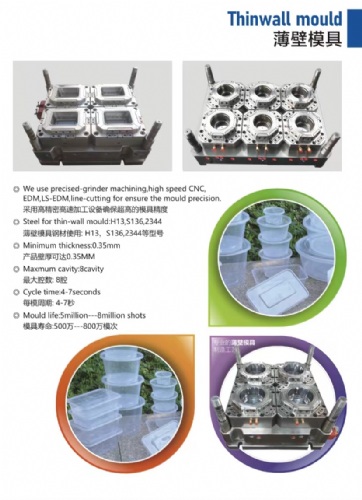

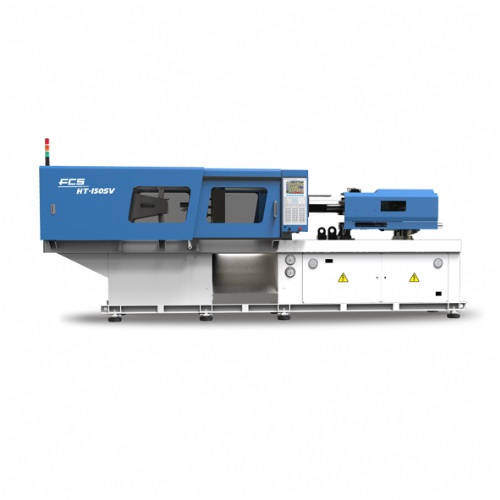

High-Speed Thin-Wall Injection Molding Machine

-

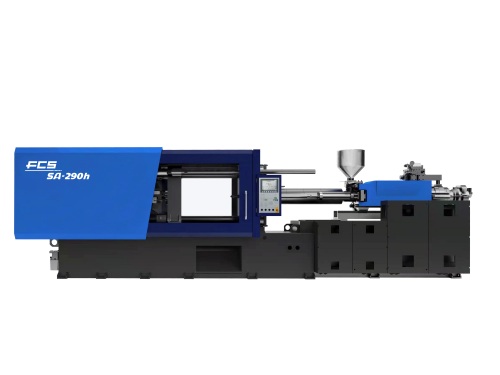

Advanced Servo Hydraulic Injection Molding Machine

-

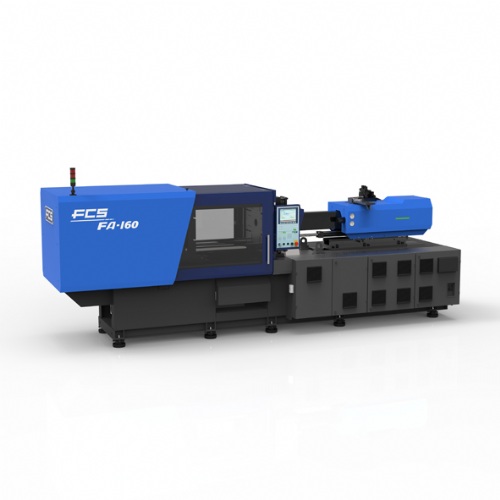

Servo Power-Saving Injection Molding Machine

-

All-Electric Injection Molding Machine

-

Two-Platen Injection Molding Machine

-

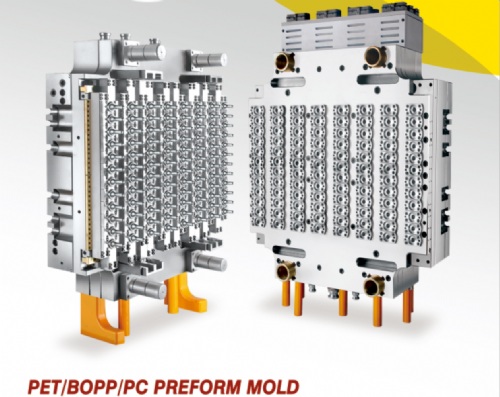

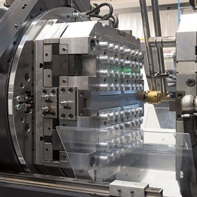

PET Preform Injection Molding Machine

-

iMF4.0 Intelligent ManuFactory

Products you may be interested in

Highest Rated Products